If I asked you where vaccines come from, you probably wouldn’t guess the seemingly indestructible and oft-forgotten succulent in the windowsill next to your desk. Traditionally, vaccines have been produced in cell lines, eggs, and more recently via “in tubo” enzymatic reactions, in the case of mRNA vaccines. While eggs and tubes are great, one ambitious company in Canada is going about things a little differently. They are using plants to grow vaccines.

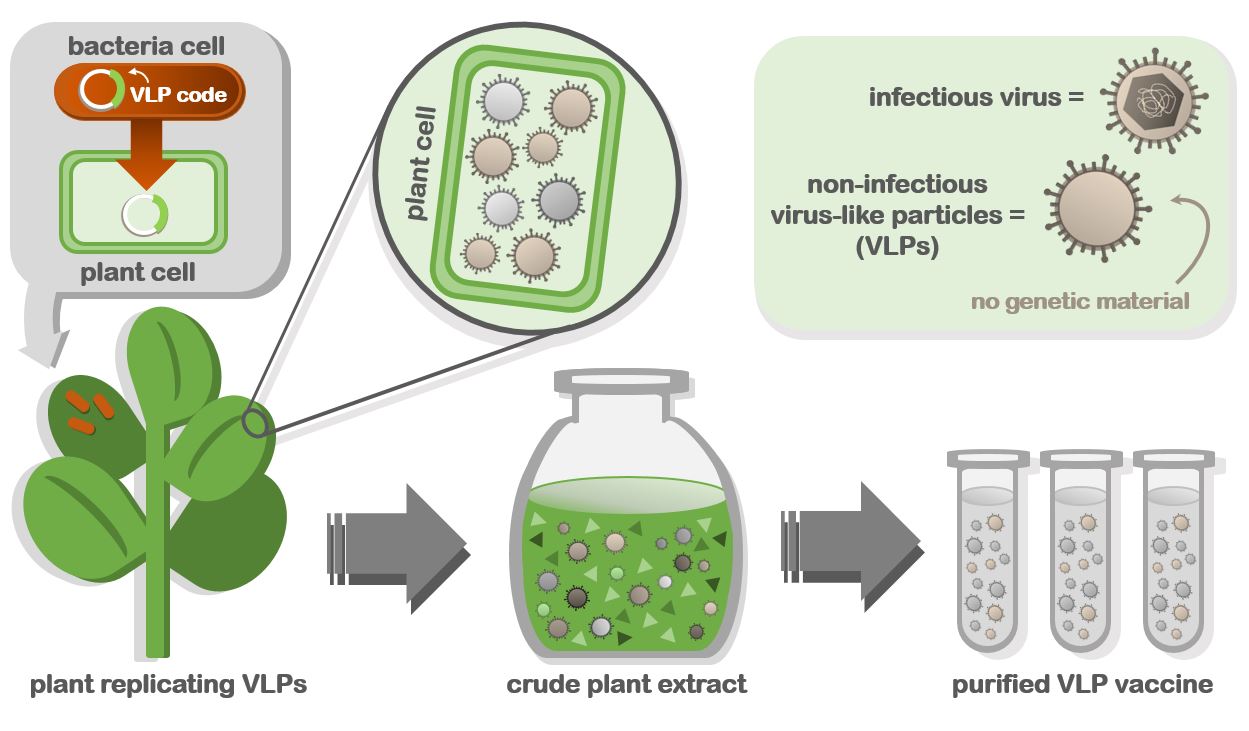

Medicago is a Canadian biopharm company that specializes in nutraceuticals and plant-based medicines. The company has harnessed the substantial growing power of leafy greens for over 20 years. So, how exactly does a plant produce a vaccine? Medicago uses plants as bioreactors capable of generating the desired product in high volumes. The company first employs a bacterial delivery system to inoculate their plants with the coding material required to produce virus-like particles (VLPs). VLPs are non-infectious and incapable of replicating; therefore, there is no opportunity for VLPs to mutate or pose any communicable threat to humans. After the plants have been successfully seeded with the VLP instructions, they are left “to simply be” and grow freely. Once the plants have reached an appreciable size, they are harvested, pureed into crude extracts, and then purified to remove all planty contaminants except for the VLPs. After the purified VLPs pass quality control, they are ready for vaccination.

Plants make ideal biological factories for producing vaccines. Cell-derived products can be difficult to properly scale from petri dishes to industrial-sized “bio-tanks”. Fortunately, thanks to agriculture, the commercial-scaling of plants is already well established. Unlike eggs and cell lines, plants don’t require specific mammalian-derived growth factors, specialized media, or sophisticated incubators. The needs of a plant can be met with light, water, and standardized micronutrients, which can be supplied by readily available fertilizers; therefore, the only factor truly limiting their potential as vaccine powerhouses is merely space.

According to a clinical study with 24,000 adults from the United States and five other countries, Medicago’s plant-derived vaccine (COVIFENZ) has shown 71% efficacy at preventing COVID. No serious adverse side effects have been reported post vaccination. The plant vaccine is currently in Phase 3 clinical trials and is being assessed for its protection against the recently emergent Omicron variant. As Medicago prepares their vaccine for government approval, they are gearing up their production facilities. If their vaccine is approved, the first mass-produced plant vaccines will actually be made right here in the North Carolina Triangle! Specifically, the vaccine will be produced in our very own “Bull City” Durham, which currently houses one of Medicago’s largest fully automated greenhouses and the latest-and-greatest purification technologies.

While the current mRNA-based COVID vaccines offer higher efficacies than Medicago’s plant-VLP vaccine, mRNA vaccines are costly. Importantly, while ~90% efficacy is technically higher than 71% by value, these numbers are simply the statistics determined during controlled clinical trials. It does not mean that a vaccine only has a 70% chance of working. Rather, it means that in a vaccinated population, there is a 70% reduction in the number of infections where the virus is being spread (as opposed to a non-vaccinated population). When it comes down to the biology, the outcome remains the same. No vaccine can be 100% effective. Breakthrough infections are always possible, but the chances of infections drastically diminish upon vaccination, whether it is with mRNA or plant-VLPs. The bottomline is vaccination stops the spread of SARS-CoV-2 and prevents both hospitalization and death during rare breakthrough infections.

As of February 2022, 4.93 billion or 64.8% of the global population has been vaccinated for SARS-CoV-2. The majority of these vaccinations are in wealthier nations with low income countries having the lowest vaccination rate of all. One reason for this disparity is due to the materials and wealth required to produce and ship the vaccines. Medicago’s plant-derived vaccine can be made using easier, cheaper, and more widely accessible tools, opening the possibility of a more globally equitable vaccine.

Vaccines are the most important tool in our arsenal for fighting the spread of COVID-19. The more types of artillery we have, the better off we are in winning the fight. Medicago’s leafy green-inspired vaccine may soon become another vital asset in our toolbelt. Moreover, this innovative plant-based technology opens the door for a whole new manner of vaccine and biologics production to be used in the future. To date, Medicago is already in Phase 2 trials for its plant-derived vaccine against influenza and Phase 1 for a vaccine against rotavirus.

The next time you’re ordering a large Green Goddess Kale smoothie at your favorite crunchy juice bar, perhaps you’ll wonder whether next year’s flu vaccine may just come from a similar vegetative concoction.

Edited by: Aditi Kothari