Think about the clothes you’re wearing right now. What were the raw resources that made those textiles? How long have you had them and how long will it be before you throw them away?

Today’s fashion industry is responsible for 2-8% of global greenhouse gas emissions according to the UN Alliance for Sustainable Fashion and is facing a monumental waste problem. Compared to 15 years ago, the average consumer is buying 60% more clothing and only keeping it for half as long. According to the Ellen Macarthur Foundation, one garbage truck of textiles is burned or landfilled every second. The industry loses about $500 billion per year because of clothing that is landfilled before ever being sold or used clothing that is not recycled. Furthermore, when clothes go to landfill and fibers degrade, dyes, specialized coating chemicals, greenhouse gas methane, and microfibers are released into the environment. Microfibers, the most common type of microplastic or small pieces of plastic less than 5 mm in diameter, are a major source of pollution of which scientists are only beginning to understand the full effects on humans and the environment.

The road to a more sustainable fashion industry is one with many facets. Imagine clothes that don’t release microfibers and are manufactured using renewable resources. But maybe most importantly imagine clothes that are made to last and be worn longer, to avoid the inevitable trip to landfill that nearly 90% of clothing produced in the current industry will make. And for clothing that is really at the end of its life, picture textile recycling becoming as commonplace as plastic recycling, versus the miniscule 13% that gets recycled today. Scientists in particular can help to tackle this problem by making strides in understanding the science of fabrics.

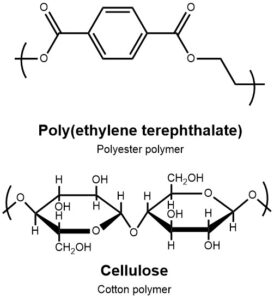

Clothing fibers are made up of polymers, long chains of molecules linked together, similar to the plastics such as polyethylene that are already commonly recycled. We already know how to break down many polymers, but the biggest challenge in textile recycling is the number of different types of fibers and therefore polymers that make up our clothes. Shredding clothes shortens polymers and weakens textile fibers, so solvent-based recycling is instead the most promising method for clothing recycling. Polymers, however, have strong intermolecular forces that make them difficult to dissolve and require special solvents to do so ‒ useful when you want your clothes not to disintegrate in the washing machine, but more of a challenge when it comes to recycling.

In order for a solvent to dissolve a polymer, it must have a larger attraction to the polymer than the polymer has to itself through its intermolecular forces, which will cause the polymer strands to untangle. Popular solvents for dissolving textile polymers include ionic liquids. These conductive salts exhibit melting points lower than 100°C and are composed of an organic cation and organic or inorganic anion. The cations and anions in these liquids create strong bonds with the polymers that allow them to dissolve. Since ionic liquids are soluble in water whereas textile fibers are not, separation of the two in order to form new, recycled clothing fibers is relatively facile.

The challenge with clothing recycling is that there isn’t one ionic liquid that will dissolve all textile fibers. Furthermore, clothing today isn’t made up of solely textile fibers or just one type of fiber, and not all clothing is of the same quality. Processing technologies will need to be developed and optimized for new vs. old clothing; for impurities including dyes, chemical coatings, and spandex; and for different blends of fabrics. There are still challenges to overcome in understanding the chemistry of fabrics, but companies today are already starting to make strides. Evrnu, based in Seattle, has developed novel fiber NuCycl from recycled cotton, and Adidas and Levi Strauss have both released limited edition collections incorporating it. In Finland, Infinited Fiber has developed a recycled cotton fiber that has been tested by brands such as VF Corporation and H&M.

Experts are optimistic about the future of clothing recycling, but as mentioned above it is only one aspect of creating a sustainable fashion industry. Furthermore, recycled clothing is still not sustainable or ethical if it is made by garment workers not earning fair wages. Some great resources for learning more about the journey to sustainable fashion include the Ellen Macarthur Foundation, Global Fashion Agenda, and Workers Rights Consortium. While scientists’ expertise is needed to further clothing recycling technology, we all have power as consumers. We can buy less, wear our clothes longer, shop and donate secondhand, shop sustainable brands, and support sustainable fashion organizations in order to help realize a more sustainable future for fashion that will be less detrimental to the planet.

Peer Editor: Katelyn Huff