It’s easy to assume that important chemical compounds are complex. However, some of the most remarkable substances are composed of simple repeating units. Here are four carbon-based structures that, while simple in their underlying composition, have revolutionized the chemical material industry.

Polyethylene

When most scientists make mistakes, it generally leads to pulling of hair and gnashing of teeth. However, some rare investigators get lucky. For instance, the the development of polyethylene consisted of a series of fortuitous mistakes. In 1894, Hans von Peckmann produced the first credited batch of polyethylene as an unintentional chemical byproduct. It was rediscovered four decades later by Eric Fawcett and Reginald Gibson when systemic oxygen impurities induced its polymerization. Karl Ziegler later discovered a modern catalyst widely used for the synthesis of polyethylene when nickel leached from the stainless steel surfaces used for a separate chemical reaction.

At first glance, polyethylene looks like nothing special, largely consisting of a chain of polymerized methylene (-CH2-) units. However, its great advantages stem from its low cost and ability to be readily modified into a variety of forms with different chemical properties. Today, it is an integral part of the trillion dollar plastics industry, with applications ranging from food packaging to electrical insulation.

Teflon

Move over, Slick Rick. Replacing the hydrogen atoms of the polyethylene backbone with fluorine atoms leads to polytetrafluoroethylene, one of the slickest materials known to man. More commonly known as Teflon, its origin is attributed to another accidental discovery. While Roy Plunkett was attempting to produce Freon gases for refrigeration, a waxy substance spontaneously formed instead. Further characterization of this material revealed several interesting chemical properties, including high melting points and extraordinary slipperiness.

The extremely low friction properties of Teflon have led to the Guinness Book of World Records describing Teflon as “equivalent to wet ice on wet ice.” While it’s perhaps most well-known for its use in non-stick cooking pans, its applications vary from interior linings for airplanes, spacecraft, and the first atomic bomb to aerodynamic coatings for race cars.

Fullerenes & Carbon Nanotubes

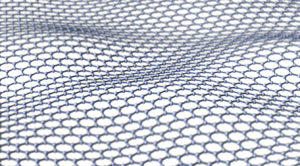

Scientists often display an insatiable desire to name new structures after themselves or other scientific pioneers. In rare cases, this tendency can transcend disciplines. WhileWhen attempting to recreate carbon-containing structures found in space, a team lead by Harry Kroto created a molecule composed purely of sixty carbon atoms. However, its exact structure remained puzzling. While brainstorming possible structures, Collaborator collaborator Richard Smalley recalled spherical structures designed by architect Buckminster Fuller while brainstorming possible structures. Using this as inspiration, Smalley (with paper, scissors, and limitless patience) was able to reproduce a similar configuration that fit the proposed chemical formula of the discovered compound. This structure, which consists of carbon atoms arranged in a repetitive hexagonal lattice, was subsequently named ‘fullerene’ (also nicknamed ‘buckyballs’).

While fullerenes themselves have a variety of biomedical and industrial uses, they have largely been surpassed by related cylindrical structures called carbon nanotubes. Developed in 1991 by Sumio IIjima, carbon nanotubes have been widely used for targeted drug delivery, solar cells, electronics, and several other applications. Interestingly, carbon nanotubes are considered a potential replacement for the long entrenched silicon-based technology that drives the computer industry.

Graphene

Everyone is well acquainted with graphite, most recognized for its use as a non-toxic replacement for lead in pencils. However, graphite acquires unusual properties when it is reduced from bulk material to a single layer of carbon, also known as graphene. While long proposed as a theoretical structure, graphene was not isolated until 2004. In a project that could only be described as a graduate student’s worst nightmare, Andre Geim and Konstantin Novoselov produced graphene by peeling single layers off of graphite using scotch tape. Mercifully, an explosion of research following this discovery has led to easier and more reproducible methods for manufacturing graphene.

While the structure of graphene is essentially that of an unraveled fullerene or carbon nanotube, it has many unique physical characteristics, including high electrical and thermal conductivity, flexibility, and ridiculous strength (it is considered one of the strongest materials ever created). As a result, the potential applications for graphene evoke thoughts of a utopian future, including ultrafast electronics and flexible supermaterials. While these applications will take time to be fully realized, the future for graphene looks exceedingly bright.

Chemical materials composed of relatively simple backbones can have astonishing macroscopic properties. Simple modifications, like the replacement of individual atoms or the raveling and unraveling of different structures, can lead to vastly different chemical and physical characteristics. This tunability forges a wide open future for the field of material chemistry and its impact on everyday consumers alike.

Peer edited by Tamara Vital.