It’s October and that means spooky season is upon us. Cheery neighborhoods are transformed into chilling displays of the macabre as front steps are lined with garishly grinning pumpkins and lawns are speckled with styrofoam gravestones. Gargantuan spiders bedeck houses shrouded by massive spider webs. While most of us may find spiders creepy and are repulsed if we have the misfortune of running into their sticky webs, surprisingly enough, humans have been using spider silk for centuries. The most recent application? Creating glowing spider silk as an infection detection tool.

Waterproof, stretchy yet stronger than steel, and thinner than hair, spider silk has been used by humans for countless endeavors. Spider silk has been spun into golden capes, violin strings, and New Guinean fishing nets. Ancient Romans used the silk to squelch bleeding and bandage wounds. The first scientific study published on spider silk applications dating back to the 18th century states that spider silk can encourage tissue regeneration.

Although it’s dubious that spider silk is actually antimicrobial, as it previously was thought to be, one of the benefits is that it is biodegradable and doesn’t harm living tissue when implanted into it. Spider silk is mostly made up of specialized proteins threaded in a unique pattern that gives the silk its impressive strength and elasticity. Proteins have already been used in sutures and other biomedical applications since they readily break down into substances familiar to the body, such as water and carbon dioxide. Now scientists are exploring fantastic applications of spider silk worthy of science fiction from using spider silk to repair damaged nerves, construct vessels and develop more environmentally friendly fashion.

Researchers at the Saint Petersburg National Research University of Information Technologies, Mechanics and Optics have tested spider silk as surgical sutures for closing, healing, and monitoring wounds for infections. Often infections follow surgeries, leading to complications ranging from cosmetic scars to even fatalities. Monitoring the presence of pathogens such as bacteria and fungi in the wounded tissue could prevent infections. To create a visual infection sensor, these scientists made glowing spider silk that dims in response to infection-causing microorganisms.

To make this glowing silk that darkens when it detects pathogens, these researchers attached carbon-dots, or C-dots, to purified and sanitized spider silk collected from Bolivian curtain-web spiders. C-dots are a new type of fluorescent substance that glow red under blue light. This glow emitted from C-dots is visible, even if the C-dots are under a thin skin layer, which can happen during wound healing. However, when exposed to infection-inducing pathogens, the C-dots can’t glow due to an energy-absorbing chemical reaction that occurs between the surface of the C-dots and these troublesome microorganisms. Therefore, C-dots act as visual infection sensors.

During testing, when the C-dot laden spider silk was exposed to higher and higher concentrations of bacteria or fungi, the silk glowed more and more faintly. It’s not just the glow abruptly switching from on to off, but the modulation of the glow that is a crucial requirement for the silk to be an infection monitor. Since a concentration of 105 bacteria or more is considered the tipping point to lead to infection, it’s necessary that the silk is sensitive to changes in bacteria concentration and reflect these changes.

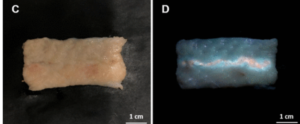

The infection sensing, glowing spider silk hasn’t been used in humans quite yet. So far these scientists have tested the glowing silk in human cells grown in a dish and on pieces of chicken skin, but their results are promising. Importantly, the addition of C-dots to the spider silk didn’t impact the health of the tissue or cause the cells to grow abnormally. The C-dot covered silk glowed brightly enough to be seen even when the silk was completely covered by chicken skin. However, this technology still needs to be further tested before it’s used to seal and monitor the healing of wounds. A major step would be to test how well this glowing silk can sense infections on live animals instead of on separated skin or cells.

Perhaps the largest obstacle facing scientists who want to integrate spider silk technology into the world is scalability. For instance, over 1 million spiders were collected, milked (yes, that’s the correct term), and released during a 3 year project to produce the aforementioned golden cape. Spiders are tricky livestock to maintain due to their cannibalistic tendencies. Instead, scientists have genetically engineered other somewhat more cooperative organisms, ranging from bacteria, yeasts, tobacco, mice, and goats to produce spider silk proteins, with mixed success. Six kg of tobacco leaves yielded 400 milligrams of spider silk proteins. For reference, that’s extracting less than half a paper clip’s weight in spider silk from just over 13 pounds of tobacco leaves. Despite these snags, scientists continue to develop novel ways to harness this alluring silk on the industrial scale.

If I see a trick or treating Spiderman this Halloween I’ll consider an alternative universe where instead of spraying spider silk out of their hands, this Spiderman has glowing spider silk healing them.

Peer Editors: Alayna Mackiewicz and Taylor Tibbs